Solutions Overview

At Autoedge, we understand that true efficiency goes beyond isolated automation. It requires a fully integrated ecosystem—from input material storage and internal transfers, to automated assembly, packaging, finished goods handling, and streamlined supply chain logistics. Our solutions are designed to provide seamless coordination across the entire production workflow, helping you by enabling smart, connected, and scalable manufacturing, Autoedge empowers you to transform your production floor into a future-ready intelligent factory

Few key applications solutions,

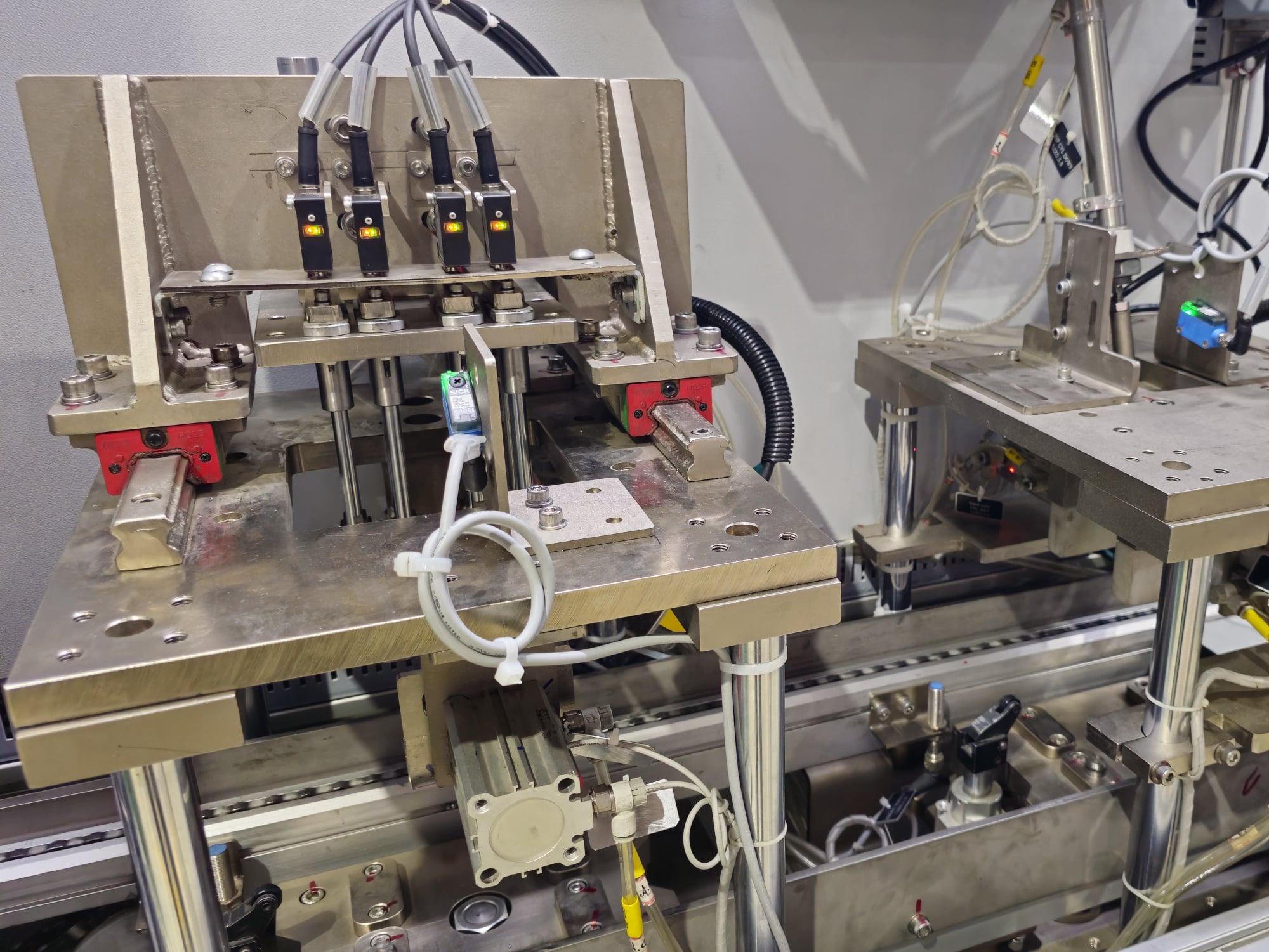

1. Assembly lines

2. Inspection lines

3. Work Cells

4. Manufacturing Automation Solutions

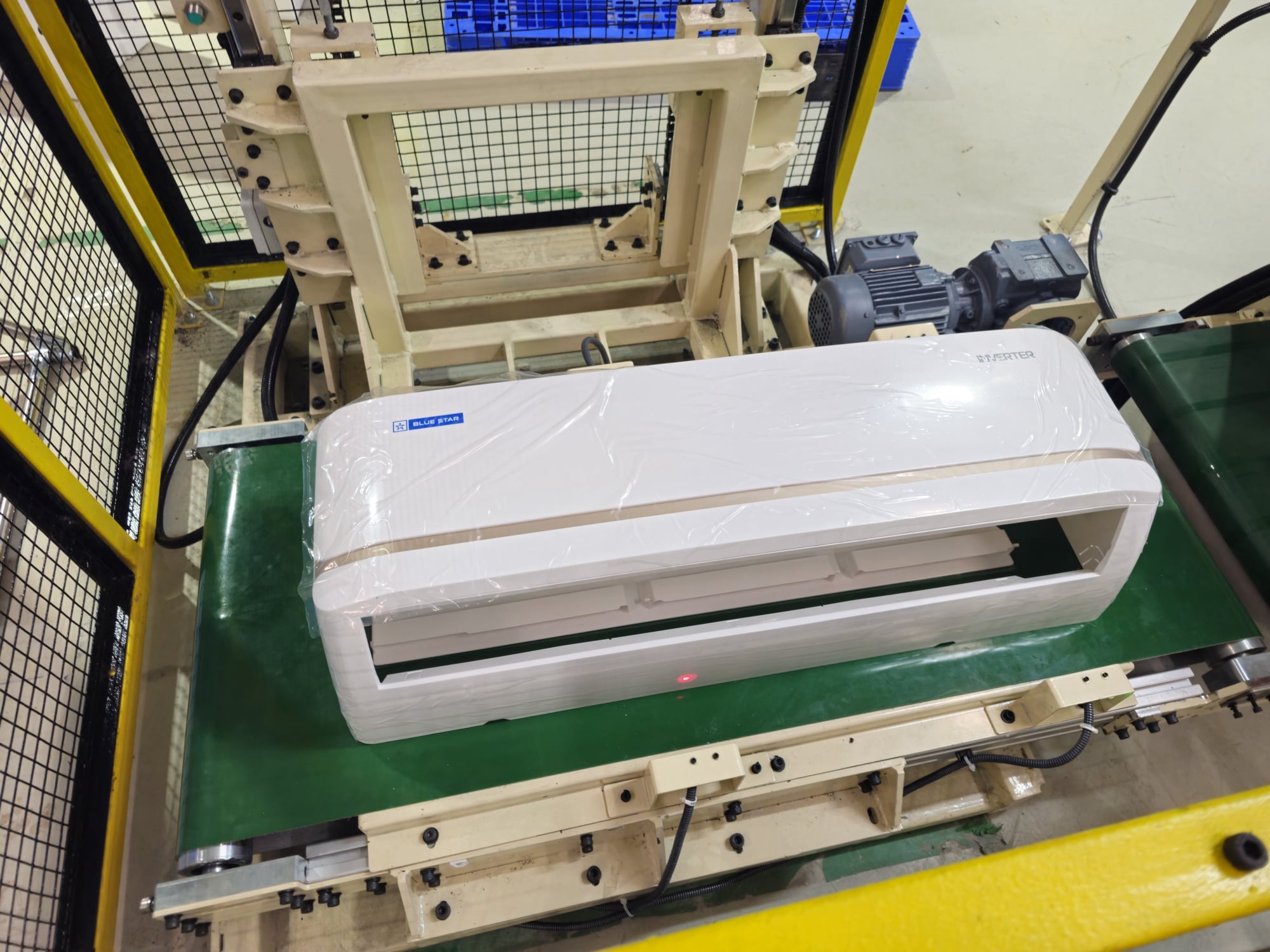

5. Standard Conveyors

FOLLOW US!